Perentie Badger Prototype (1993)

This article was published in the Australian Paintballer magazine in October 1993.

As you all are no doubt aware Australia is a fairly small market for paintball equipment. In the past very little has been manufactured locally. The only items being fill stations, barrel plugs, vests and a few small gun parts.

Since the ban on the importation of semi-auto paintball guns there has developed a big demand for this type particularly for competition use. The value of those guns that arrived prior to D-day has risen in some cases to ridiculous levels. As for the import regulations, well they suck to put it politely. You and I know that a baseball bat is more dangerous than a paintball gun. Anyway, enough of that and on with the story. After the ban, rumours spread like wildfire about locally designed paintball guns. If they had all eventuated we’d be up to our eyeballs in the things.

Last Sunday I had a chance to examine one of those rumours, a prototype blow-forward paintball gun made in the small town of Seville which is just outside Melbourne. We had arranged to meet at Damien Fitzgerald’s paintball field in Cockatoo at 10am. This suited me just fine as I was playing that day anyway with members of the Lounge Lizards and Red Amoeba paintball teams.

Bruce Roberts and Darren Hayes arrived around 10.30am as I was busily locating some spare equipment to lend to some guests from West Australia. The prototype, “The Badger” was quickly unwrapped under my critical gaze and the first thing that struck me was how well finished it was. The grip and frame assembly was machined from aluminium plate with the grip being drilled to provide the gas line for the bottom line bottle fitting. The stainless steel trigger/sear mounted in the frame was of massive proportions and looked unbreakable. The bolt and valve assembly were constructed from a mixture of brass and stainless steel with all parts being well finished and looking very rugged. The barrel assembly which can be removed from the gun by undoing a single screw consisted of a stainless steel breach and feed port connected to a floating brass barrel. The barrel being suspended inside a larger aluminium tube. Next to the feed port was a spring clip holding a plastic anti-double feed device. Evidence of care and attention to detail showed on every part of this gun with the whole gun being covered in a tough black powder coat finish.

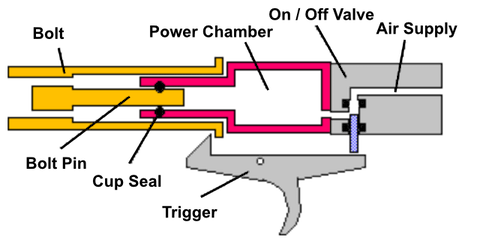

The method of operation is similar to the Auto-Mag. The major difference being that this gun has no gas regulator to adjust velocity. It relies on a restricting screw in the bolt to regulate the gas flow. The primary or maximum velocity being determined by the size of the gas chamber behind the bolt.

After gassing up we headed out to the shooting range for some test shots. The first few shots over the chrono gave 245 feet per second. Not bad since Bruce hasn’t got a chronograph of his own yet. The trigger pull was crisp with a good clean release and feel. Its accuracy was impressive and at least equal to a good pump gun. The gun shot well considering that it was raining and moisture was causing everyone to have paint problems.

The only problem we had was with the main o-ring in the power tube assembly. The nitrile o-rings suffering from the cold of rapid firing and the sudden pressure changes. It seems that o-rings absorb gas and can suffer from explosive decompression. They get the “Bends” as tiny bubbles form inside because of the sudden pressure changes that occur when the gun is fired. Other o-rings have been ordered which Bruce said would cure this problem. Bruce Roberts is more than qualified for this project. Because, apart from being a qualified Fitter and Turner he also holds the army trade of Fitter Armament.

The following week we drove out to Deon Gilbert’s ML Skirmish field at Coldstream to take some more photographs. It was raining when we arrived but the outlook was promising. After the photo shoot the Referees commandeered the gun and clutching large bags of paint descended on the shooting range. Bruce looked on with a wide grin as 300 to 400 paintballs streaked down range in about 5 minutes.

I asked if the production models would differ in any way from the prototype. Bruce stated that apart from a couple of minor improvements and a decision on how the frame was to be made, cut from alloy plate or cast, the gun was ready for production.

The primary aim of Bruce and Darren’s company Perentie Paintball is to manufacture a gun suitable for the rental market. Once the rental model is coming off the production line other more up market models will be developed. The first guns should be available within two months. The retail price hasn’t been set yet but I’m told it will be around $800.

From what I’ve seen this gun has a good chance of being a success. We can only hope it’s just the start of a landslide of locally made paintball products.

Mike